Controlled Implosions Precision Blasting

admin2018-06-10T17:48:16+00:00JET DEMOLITION HAS OVER 30 YEARS’ EXPERIENCE IN APPLIED RESEARCH AND DEVELOPMENT OF EXPLOSIVE BLASTING AND CONTROLLED IMPLOSION TECHNIQUES FOR LARGE COMMERCIAL & HEAVY INDUSTRIAL APPLICATIONS.

We offer in-house blasting designs and project execution using our range of specialised charges, ensuring reliable results under the most demanding conditions. Our controlled implosions and precision blasting projects adhere to all legislative and regulatory requirements, and are fully managed by our certified and experienced explosive’s engineer.

Our implosion of the 14-storey HG de Witt Building in Pretoria, South Africa, earned us the Explosive Demolition Award at the 2017 World Demolition Awards. This recognition further strengthens our commanding position in the industry as South Africa’s premier explosive demolition service provider.

Optimised hybrid demolition methodologies are devised using a range of techniques specifically tailored to the project, taking all external and structural factors into consideration. These methodologies include:

- Physical separation of structural elements by Diamond Cutting;

- Drilling and coring;

- Mechanical sectional demolition;

- Development of Blast Management Plans;

- Traffic and pedestrian evacuation and control;

- Waste Management Plans;

- All approvals from relevant authorities;

- Procurement and charging of explosives;

- Final implementation and execution of the blast;

- Clean-up and removal of all debris.

Petrochemical and Cold Cutting

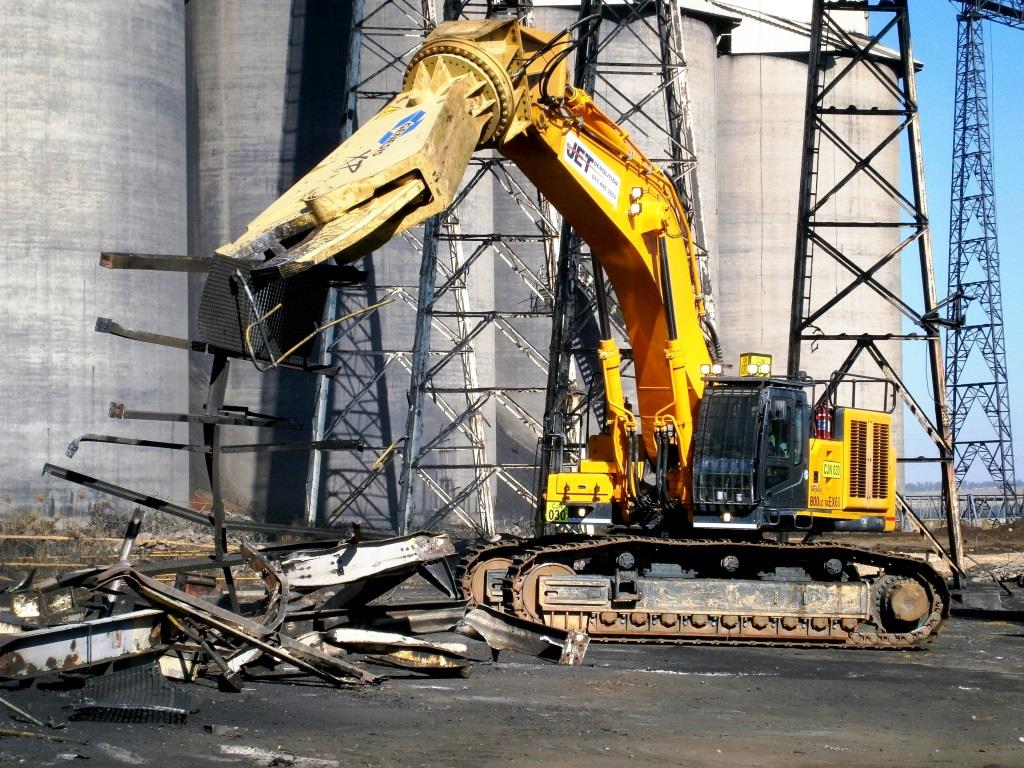

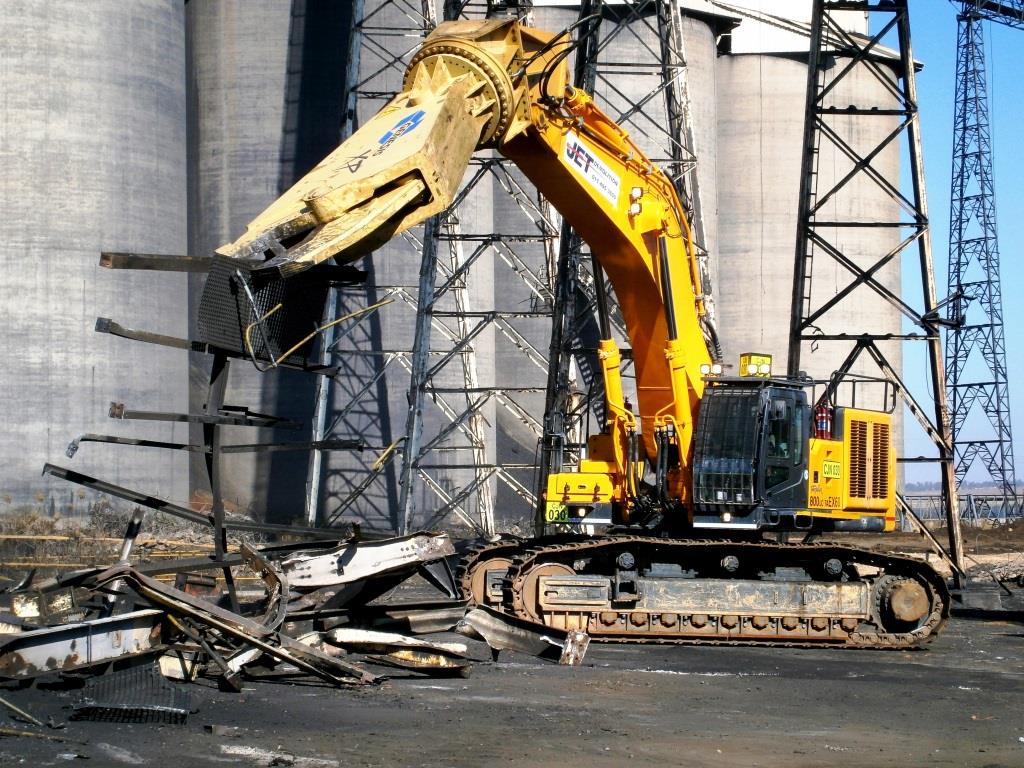

admin2018-06-10T17:13:43+00:00JET DEMOLITION OWNS A VARIETY OF SPECIALISED COLD CUTTING DEMOLITION TOOLS AND ATTACHMENTS SUITED TO OUR FLEET OF DEMOLITION MACHINES.

Our innovative techniques and demolition methods minimise sparks and eliminate flame cutting, thereby resulting in safer, quicker and more controlled demolition of structures in highly flammable and volatile environments.

Our fleet includes a diverse selection of demolition shears and ripping tools of various sizes and weights, affording us the ability and flexibility to best manage the risks associated with demolition within flammable environments. Our demolition shears range from a few hundred kilograms to over 12 tonnes, and we are proud to own the largest demolition shear in Africa.

Our state-of-the-art cold-cutting equipment allows us to continue working in the most volatile environments without affecting our Client’s operational processes. Jet Demolition was the first company to introduce this technology to the South African market, and have had continued success in the field of cold-cutting.

Cold-cutting techniques introduce a new level of safety to the petrochemical environment, and limits incidental contamination of precious resources that would otherwise not have been avoidable using less advanced techniques. We have successfully completed in excess of 90 projects on live petrochemical plants, and have had an ongoing presence in one of South Africa’s largest petrochemical facilities for over 15 years. We have successfully completed projects in:

- Hexane Plants;

- Chemical Plants;

- Petrochemical Facilities;

- Fuel Tanks and Storage Facilities.

Petrochemical and Cold CuttingA

admin2018-06-10T17:11:34+00:00JET DEMOLITION OWNS A VARIETY OF SPECIALISED COLD CUTTING DEMOLITION TOOLS AND ATTACHMENTS SUITED TO OUR FLEET OF DEMOLITION MACHINES.

Our innovative techniques and demolition methods minimise sparks and eliminate flame cutting, thereby resulting in safer, quicker and more controlled demolition of structures in highly flammable and volatile environments.

Our fleet includes a diverse selection of demolition shears and ripping tools of various sizes and weights, affording us the ability and flexibility to best manage the risks associated with demolition within flammable environments. Our demolition shears range from a few hundred kilograms to over 12 tonnes, and we are proud to own the largest demolition shear in Africa.

Our state-of-the-art cold-cutting equipment allows us to continue working in the most volatile environments without affecting our Client’s operational processes. Jet Demolition was the first company to introduce this technology to the South African market, and have had continued success in the field of cold-cutting.

Cold-cutting techniques introduce a new level of safety to the petrochemical environment, and limits incidental contamination of precious resources that would otherwise not have been avoidable using less advanced techniques. We have successfully completed in excess of 90 projects on live petrochemical plants, and have had an ongoing presence in one of South Africa’s largest petrochemical facilities for over 15 years. We have successfully completed projects in:

- Hexane Plants;

- Chemical Plants;

- Petrochemical Facilities;

- Fuel Tanks and Storage Facilities.

Heavy Industrial Demolition

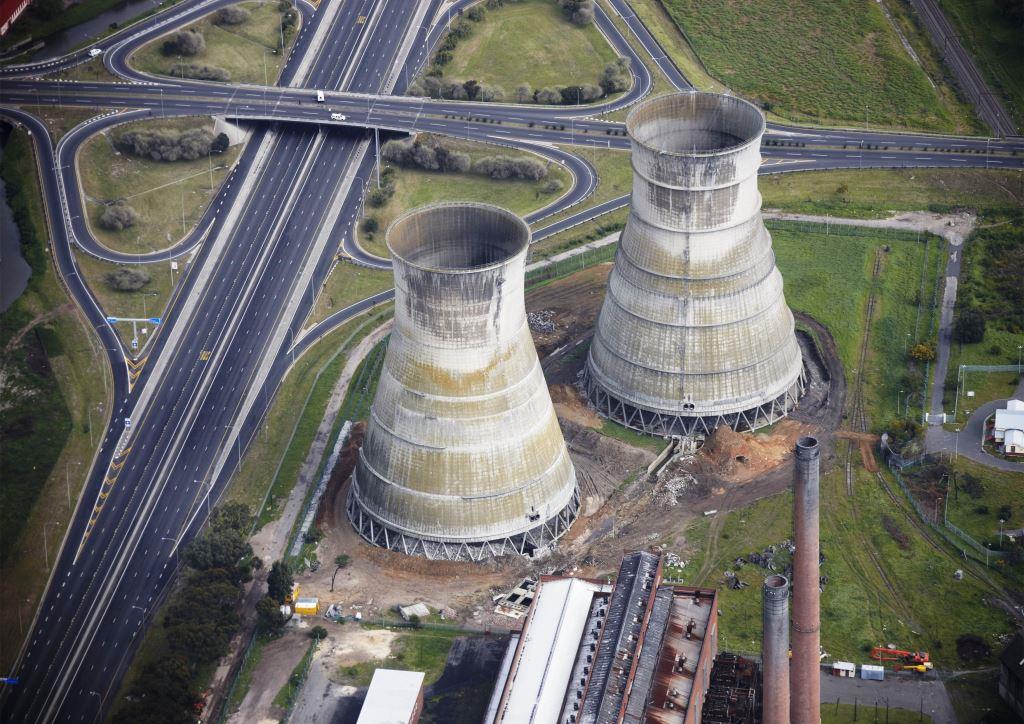

admin2018-06-10T05:51:18+00:00OUR INNOVATIVE, TECHNICALLY ADVANCED METHODS AND STATE-OF-THE-ART EQUIPMENT ENABLES US TO TAKE ON THE MOST COMPLEX HEAVY INDUSTRIAL DEMOLITION PROJECTS.

By taking a holistic and practical approach to demolition activities, we have developed and patented a range of highly specialised demolition tools and methods with the primary focus on safety. Our sites are managed by experienced, full-time Site and Safety Professionals, and are supported by a fully staffed Engineering team.

Each project is planned meticulously, and we carefully select the most appropriate methods, plant and personnel to undertake the work with minimal disruption to our clients’ operational requirements. We have extensive experience in sectional demolition of large industrial and mining plants still in operation where access is restricted and vital plant services are present and in close proximity.

Our fleet, in excess of 60 items of specialised demolition machines ranging from a 1 tonne skid steer unit to a 102 tonne high reach excavator, offers flexibility in pairing the ideal plant and equipment to suit the projects’ requirements. Through careful application of a wealth of experience, we are able to offer our clients solutions that are economical, rapid and risk-averse.

We serve all heavy industry, including:

- Automotive Manufacturing

- Chemical and Pharmaceutical Manufacturing;

- Petrochemical;

- Power Generation;

- Steel and Glass Production Facilities;

- Mining Facilities.

Partial Demolition of Dam Walls for Rehabilitation

admin2018-06-10T05:51:18+00:00REHABILITATION OF DAM WALLS USUALLY REQUIRES DEMOLITION OF REDUNDANT PORTIONS OF MONOLITHIC BLOCKS. JUDICIOUS SELECTION OF DEMOLITION METHODS AND THEIR APPLICATION TECHNIQUES ARE VITAL TO A CONTROLLED AND PRODUCTIVE PROJECT.

Through years of applied demolition research, Jet Demolition is able to offer an integrated approach to dam rehabilitation. Hybrid solutions are developed to suit specific, on-site conditions, whilst protecting the structural integrity of the remaining concrete.

Various drilling and coring methods are applied to generate blastholes of pre-determined depths, diameters and alignments, in strict accordance with our in-house blast-design, where the nature of the works to be undertaken warrants controlled blasting of spillways and structural elements.

Detonation causes both shock wave and gas penetration energy transfer to concrete structures. It is thus critical to ensure physical separation of the elements combined with careful and considered selection of blasting applications, to ensure reliable and predictable results, without residual damage to the remaining concrete. Jet Demolition offers Micro-Blasting techniques, specifically developed for dam-wall applications.

Blasting may not be appropriate in every instance. Jet Demolition has successfully completed numerous dam wall demolition projects, both by explosive and mechanical means.

Our range of dam-specific services include:

- Vertical and Horizontal Drilling and Coring;

- Blasting;

- Diamond Wire Rope Cutting;

- Mechanical Breaking using specialised demolition tools.

Demolition Cost Assessments

admin2018-06-10T05:51:19+00:00JET DEMOLITION REGULARLY PERFORMS ON-SITE DEMOLITION ASSESSMENTS FOR LARGE MINING HOUSES THROUGHOUT AFRICA. OUR EXTENSIVE EXPERIENCE IN THE DEMOLITION FIELD ENSURES ACCURATE ESTIMATION OF DEMOLITION COSTS AND DURATIONS BASED ON INTERNATIONALLY RECOGNISED BEST PRACTICE.

We are a technically-based company with 10 members of our staff in possession of B.Sc. & M.Sc. degrees or diplomas in Engineering, with Pr Eng, Pr Techni and SACPCMP accreditation. This background gives us the necessary technical foundation and skill to offer our Clients accurate, effective demolition estimations to supplement their Life of Mine (LoM) planning.

Prior to deployment to the site, Jet Demolition liaises with the relevant stakeholders to develop a client-specific report format for later integration into the final LoM estimation. This ensures that deliverables are in line with the clients’ requirements, and aides in creating a consistent reporting-format that can readily be updated as and when required.

Our demolition costing services include:

- Advising on feasible demolition techniques specifically suited to the on-site conditions;

- Cost estimations to demolish the structures to pre-defined limits as determined by the Client;

- Estimation on scrap tonnages that may be expected at demolition stage, thereby allowing local market values to be allocated as appropriate;

- Proposed demolition and safety standards with financial implications to be included in closure planning;

- Full confidentiality and protection of proprietary information.

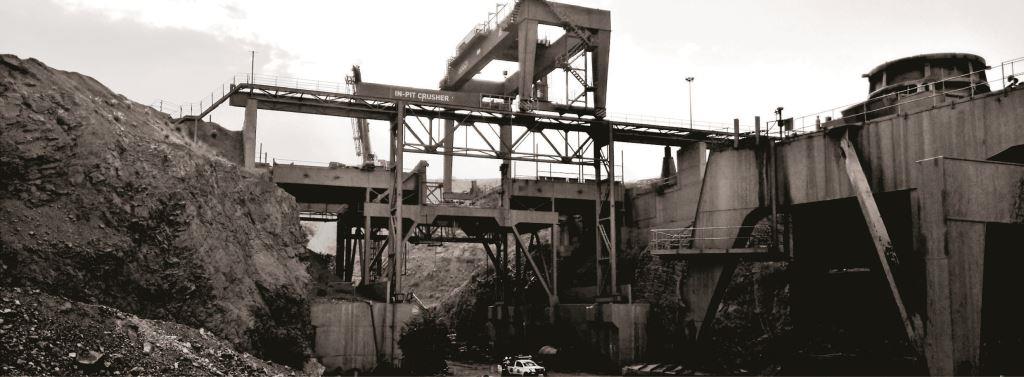

Turnkey Mine Closure and Rehabilitation

admin2018-06-10T05:51:19+00:00JET DEMOLITION PROVIDES TURNKEY SOLUTIONS TO THE MINING SECTOR, ASSISTING CLIENTS WITH DETAILED PLANNING AND EXECUTION OF MINING INFRASTRUCTURE DEMOLITION AND REHABILITATION.

Jet Demolition is one of the few international companies that provides in-house, full-range demolition services to the mining sector. Through our extensive experience in the industry, we offer detailed solutions adapted and suited to the specific project requirements, with a focus on safety, time and cost efficiency.

TECHNICAL EXCELLENCE

Our focus on technical excellence ensures reliable, consistent performance in the shortest practical time. We work in strict accordance with the guidelines of the Mine Health and Safety Act, and have completed numerous projects on both live and redundant mining sites.

RANGE OF MINING DEMOLITION SERVICES

We have successfully completed in excess of fifty turnkey projects, including a range of services specifically suited to the mining sector:

- Gold and precious metal recovery;

- Radioactive decontamination;

- Demolition of steel and concrete structures;

- Vertical and Inclined Shaft closures and permanent capping;

- Plant purchases;

- Demolition closure cost assessments and consulting;

- Asset recovery and equipment salvage;

- Temporary capping and on-site containment;

- Contaminated soil remediation;

- Corrective earthworks post-demolition.

Asbestos Abatement

admin2018-06-10T05:51:19+00:00JET DEMOLITION OFFERS ASBESTOS ABATEMENT AS AN INTEGRAL PART OF OUR TURNKEY DEMOLITION SERVICE.

Jet Demolition is registered with the Department of Labour as an asbestos contractor and is certified to safely remove all types of asbestos in strict accordance with current legislation.

Our personnel are fully trained and experienced to identify and handle asbestos including asbestos-contaminated materials. We work closely with independent occupational hygienists to develop a comprehensive asbestos plan of work and carry out compliance monitoring throughout the course of the project.

We have been undertaking challenging asbestos removal works for a number of years and own fully equipped asbestos decontamination units.

We have extensive experience in handling different types of asbestos and are fully conversant with various methods that may be prescribed to best limit the spread of airborne asbestos fibres. Techniques include dry removal, wet removal and encapsulation. Jet Demolition is one of the few companies that offers a range of specialised asbestos services to suit the specific requirements of the project.

We regularly undertake the removal of:

- Asbestos sheeting and panelling;

- Asbestos roof sheeting and tiles;

- Ceiling Boards;

- Above-ground and buried asbestos pipes;

- Insulation;

- Gaskets;

- Asbestos-contaminated soils.